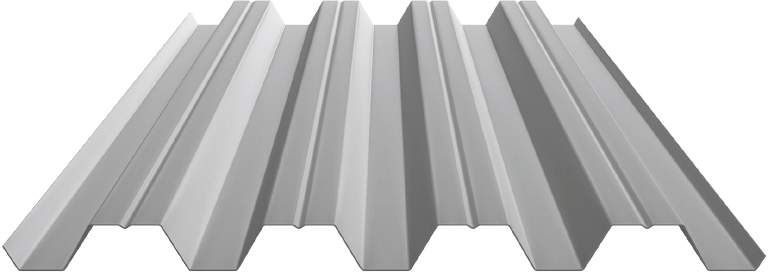

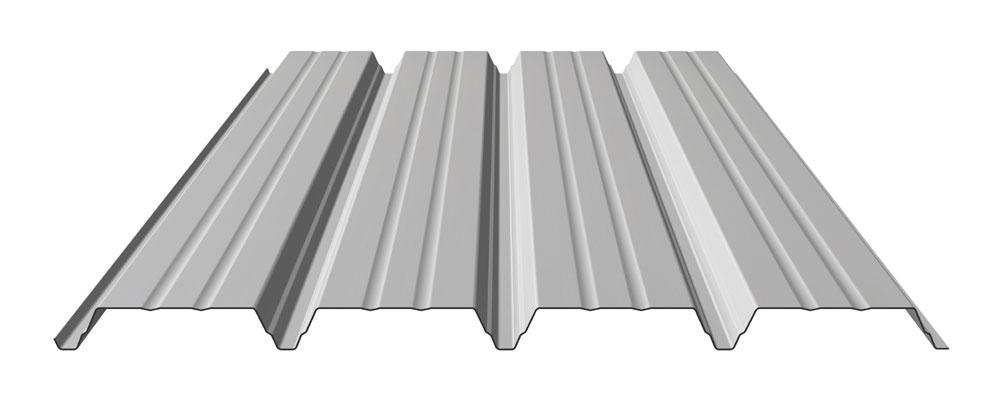

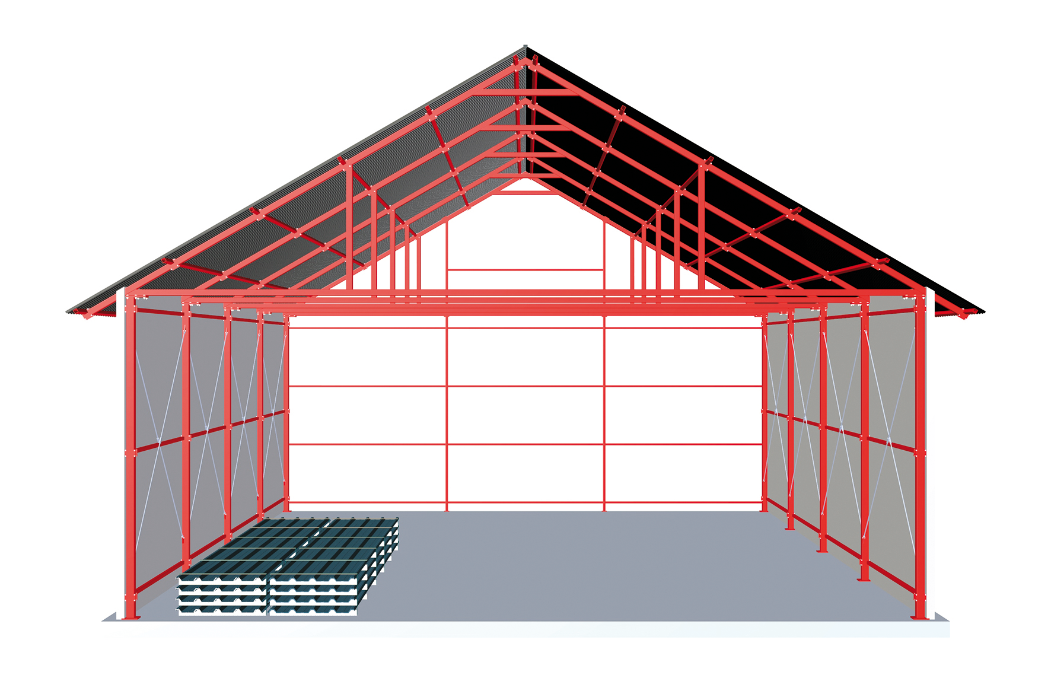

The MG 50/250 DECK profile is specially designed for application on deck-type roofs in industrial and commercial buildings. Deck-type roofs are a construction system made up of a corrugated steel sheet, an insulating core and a waterproof outer membrane. It is an ideal construction system for enclosing large roofs thanks to its speed of installation, high thermal performance, watertightness and high durability.

CE certified product according to standard UNE-EN 14782: 2006

Technical specifications

| End use | Roof Decks |

| Steel type | Standard S250GD (other types of steel on request) |

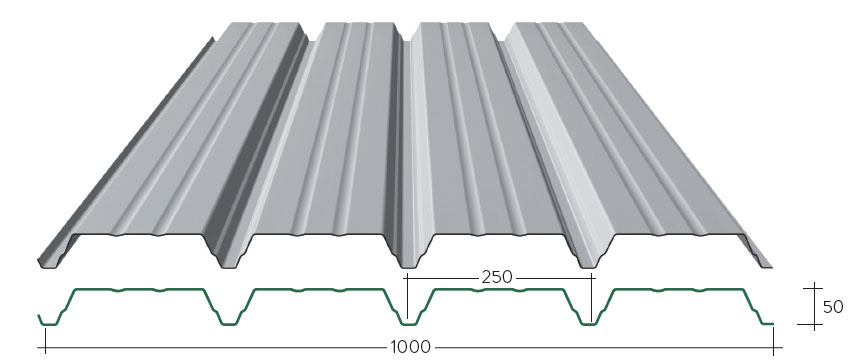

| Rib height | 50mm |

| Rib spacing | 250mm. |

| Usable width | 1.000mm. |

| Thickness | From 0.5 mm to 0.8mm |

| Length | On request (maximum 14 m). |

MEASUREMENTS AND WEIGHTS

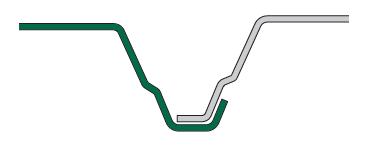

JOINT DETAIL

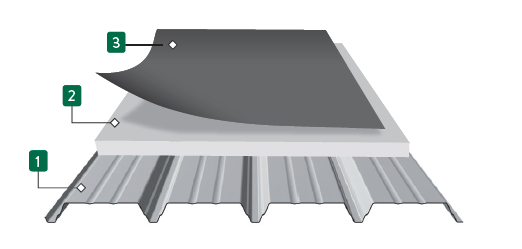

ROOF DECK COMPOSITION

1). Steel profile MG 50/250 2). Insulating core 3). Waterproof membrane

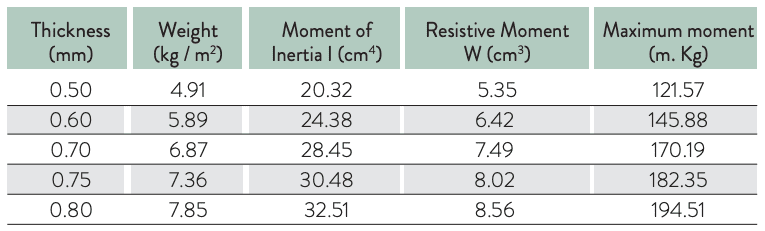

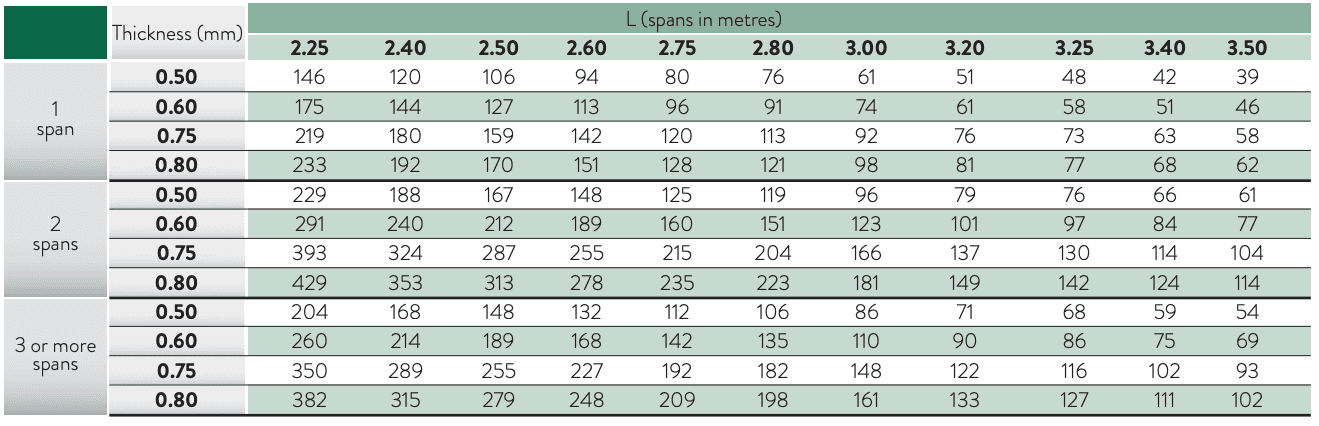

RESISTANCE TABLES

Permissible loadings kg/m2. Calculated for a Service Limit State of deformation L / 200 (maximum admissible deflection). Loads not factored. The information displayed in the tables is for guidance purposes only, with the designer being responsible for carrying out the structural calculations in accordance with the applicable regulations in each country. MAGON ACEROS will not be responsible for the inappropriate use of these tables.

Note: The colours in this catalogue are approximate. Possibility of manufacturing in other colours on request.

This profile is manufactured from cold-formed coated steel sheets according to the following standards:

| Organic coating (UNE-EN10169): | Metallic coating (UNE-EN10346): | Other finishes | Polyester, PVDF, HDX, HPS | Galvanized | On request |

In order to provide you with information about this product, we provide you with all the documentation relating to MG-50/250 DECK.

Magon Aceros offers its clients a technical department to provide support to designers and site management. We offer support for our construction system from the gestation of the project to its installation and subsequent maintenance.

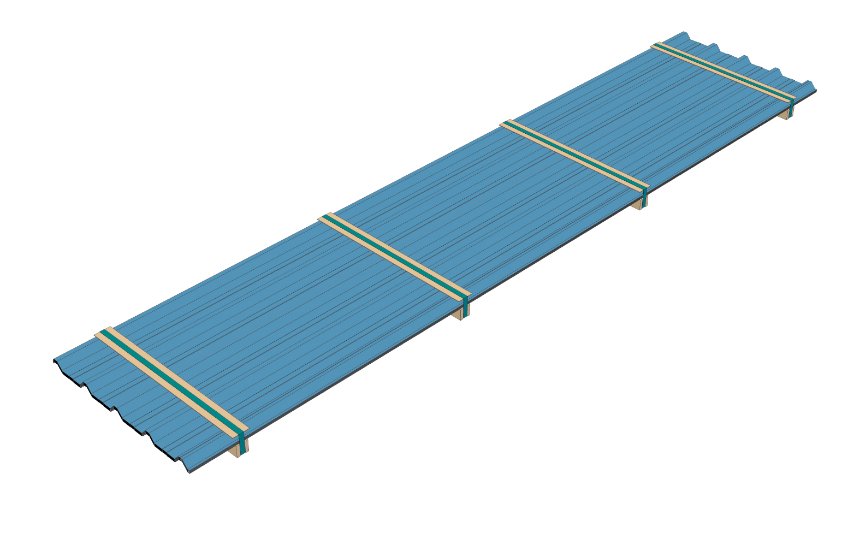

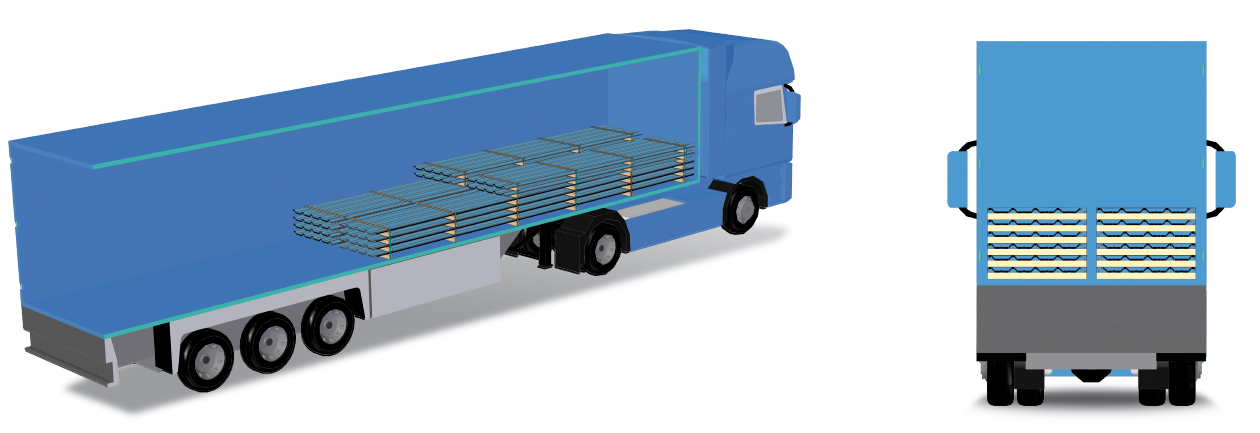

The packages are individually labeled, ensuring their traceability, and we provide a Quality Certifi cate (if requested) for pre-painted material according to the UNE-EN-10169 standard and for galvanized base material according to the UNE-EN-10346 standard. Each package is bound transversely with nylon or polyester strap, which allows stacking, without deformation of the lower packages. Finally, the products are packed with nylon or polyester straps, so that the packages can be handled both by weight and size.

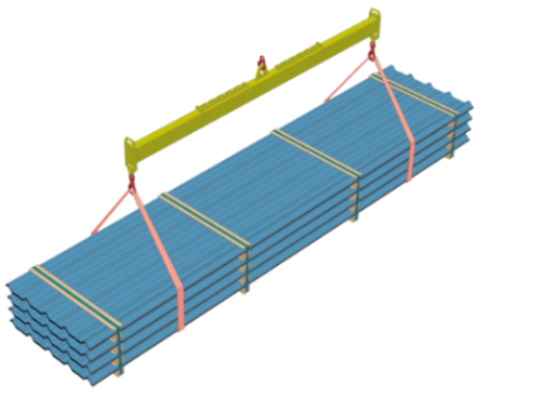

The material must be handled by means of slings for unloading, placing it in such a way that the sides of the packages are not damaged (with use of an unloading cradle) and at the correct distance so that the suspended load does not move.

Staff must always handle the sheets and profiles with safety gloves

Appropriate tools should be used to remove the sheets and profile packaging.

During transport, the packages must be well stacked to prevent the load from shifting, placing them in such a way as to avoid the accumulation of water in the event of rain. Likewise, they must travel in covered transport, MAGON ACEROS is exempt from all responsibility if these recommendations are not followed.

The packages must always be covered and ventilated, preventing them from touching the ground by means of wooden blocks or similar materials, and stacked at an angle. As the material is sensitive to humidity, condensation and rain, the infiltration of water can lead to the formation of “white rust” which, although not harmful to the material, can mar the material’s appearance.

When damage that affects the coating occurs during the handling of the panels, proceed as follows:

When the zinc coating is visible:

- Clean the surface to be repaired

- Apply an epoxy-polyurethane type primer on the affected area

- Apply a coat of acrylic-polyurethane paint over the primer in the same shade as the repaired surface.

When painting over pre-lacquered paint:

- Clean the surface to be repaired

- Apply a coat of acrylic-polyurethane paint in the same shade as the repaired surface

For proper maintenance of our material, we recommend cleaning any residue that could cause water retention on the roof (mould, vegetation, any type of debris …).

In addition, we recommend maintaining the drainage of rainwater and washing the wall panels and roofs (if detergent is used, it must be with a neutral PH).