INNOVATION IN PROCESSES AND INSTALLATIONS

MAGON EMPRESAS has contributed in no small way to the technological and productive revolution in the sector: simplifying processes, optimizing manufacturing lines, developing the advanced control of processing and surface technologies, finding the use of new materials and qualities, and constantly searching for sustainable solutions, all of which has marked our evolution and led to improved competitiveness in our processes. Nowadays, MAGON EMPRESAS is deeply involved in projects that concern:

- Process integration flexibility in the production chain.

- Reduction of energy consumption and raw materials.

- Smart manufacturing.

We always have the aim of becoming more efficient, fast and competitive, providing our customers with products with an excellent value for the money.

PRODUCT INNOVATION

Since its beginnings, MAGON EMPRESAS has offered many innovations related to steel products or materials to our customers in order to meet their needs. This has led to a continuous and constant expansion of the products available in all our sectors:

- Agro-food: continuous expansion of the range of punching holes in agricultural profiles and greenhouse profiles, as well as using the sector’s most efficient and durable materials.

- Construction: new products for new technical and aesthetic challenges, including: DECK covers, new finishes, range of colors, new profiles with superior aesthetic and technical functions.

- Photovoltaic: a wide range of profiles and ability to adapt ad hoc to the technical needs of each order from our customers.

MONITORING THE PRODUCTION PROCESS

The production processes are monitored from the beginning to the end of production, entirely controlled by computer and constantly supervised, which allows for the early detection of any incidents, and also optimizing the process.

HIGH QUALITY STEEL GUARANTEED

MAGON EMPRESAS uses top quality raw materials for manufacturing high quality and cold-formed galvanized structural steel sheets and Magnelis® steel manufactured by the leading steel companies in the sector. In all cases, our products are SVHC-free (“Substances of very high concern” which have serious effects on health and the environment, such as heavy metals), in compliance with current European REACH regulations.

MAXIMUM DURABILITY

MAGON EMPRESAS uses the latest technologies for metal coatings (Polyester, PVDF, HDX, HDS, PVC, galvanized) to provide customers with the most appropriate solution for their needs.

MAGON EMPRESAS Technical Departments advise our customers on the best coating for each specific use (food, farms, livestock, cold rooms, photovoltaic installations, etc.) and type of building (industrial warehouse, residential house, shopping center, modular housing, etc.), and taking into account the environment where it is installed, such as the humidity and temperature, among other factors, to guarantee maximum durability and compliance with current regulations.

FLEXIBILITY AND RESPONSIVENESS

We offer our customers a wide range of production facilities (profiling machines, bending machines, sandwich panel manufacturing lines, etc.) which are constantly being updated,

The manufacturing line designed is to include specific requirements from the very beginning. In this way, and using our experience, we can efficiently adapt to any of our customers’ needs.

PRODUCTION CAPACITY (YEARLY)

- 250.000 M2 Insulating sandwich panels

- 000 Tons of metal cladding

- 000 Tons of flashing and accessories

- 000 Tons of industrial purlins

- 000 Tons of agricultural holding posts

- 000 Tons of photovoltaic structures

CONTROL OF RAW MATERIAL

All raw materials are weighed and inspected upon arrival at the MAGON EMPRESAS facilities through specific reception controls for each type of material. Additionally, controls are incorporated at the beginning of the production process which reconfirm the required parameters so that all the products meet the highest quality standards and perform up to the applicable standard.

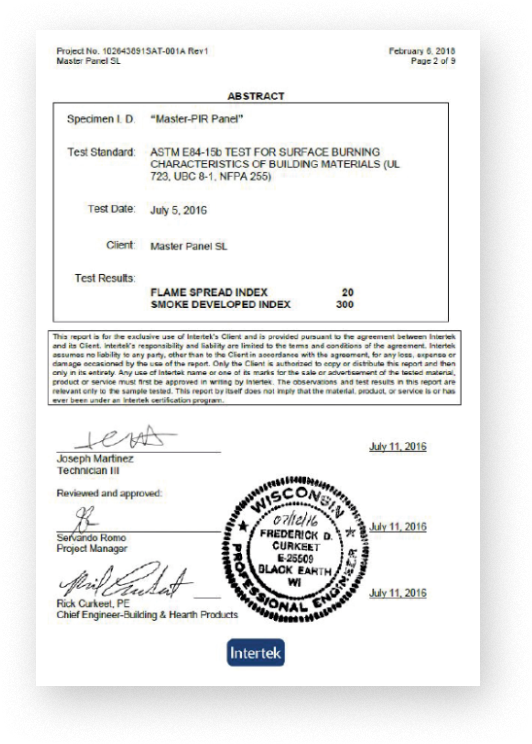

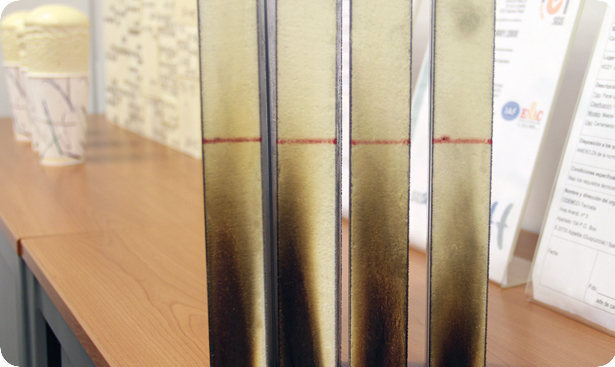

PRODUCT QUALITY CONTROL

MAGON EMPRESAS carries out strict quality control on all its products, both during the production process and on the final product. In the case of insulated sandwich panels, some of the tests are for fire resistance, thermal conductivity, tensile, ductility, compression and traction, thickness of the insulating core and dimensional controls, and many other factors. For all other products, dimensional and geometric tests are carried out, quality control examines punched holes and drill holes, etc.

LABORATORY

MAGON EMPRESA has specific procedures which utilize their laboratories to guarantee the quality of products certified with the ISO 9001 seal. On-site audits of production processes and annual test campaigns guarantee MAGON EMPRESAS quality in their factories.

GUARANTEED TRACEABILITY

All MAGON EMPRESAS factories share a modern identification and traceability system for all the materials used in the manufacturing and shipment of each order. We know, among other things, which coil has been used, the tests that were carried out, which manufacturer made it, in which order it was purchased, which orders used the same coil, etc. Using this traceability, keeping track of each order is possible, from when it’s received at the factories until when the finished product is delivered to the customer.

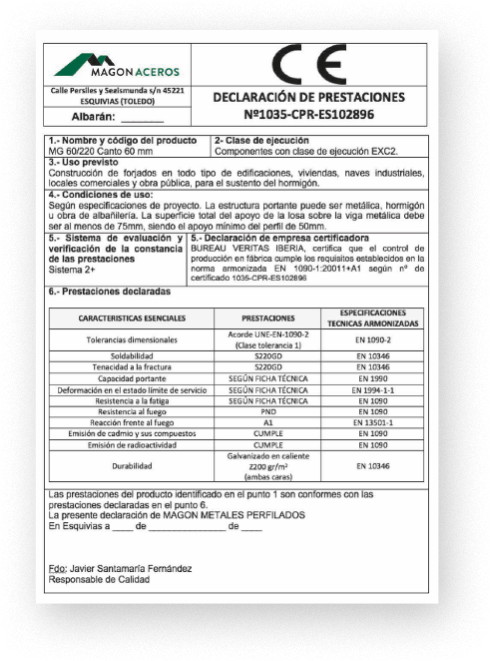

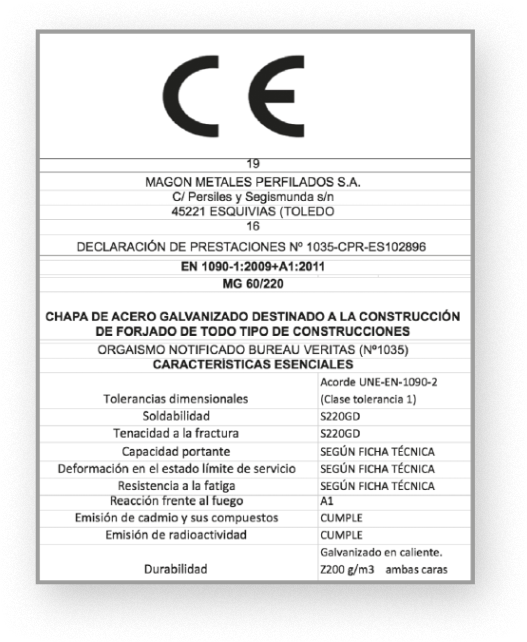

COMPANY CERTIFICATE

All our factories have implemented extremely rigorous controls in our production process to guarantee the highest standard of quality to our customers, endorsed by the ISO9001:2015 certification.

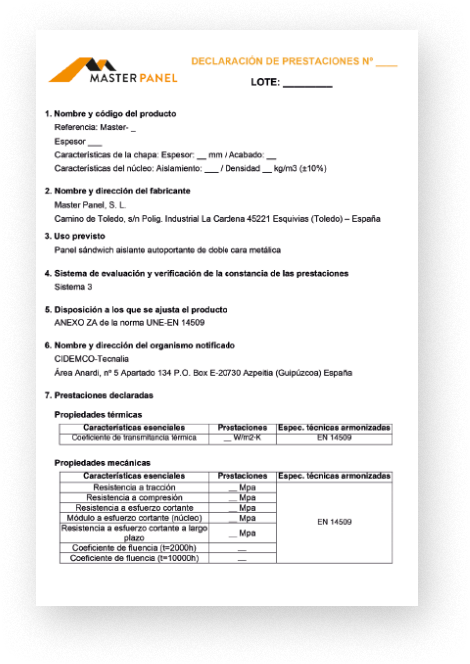

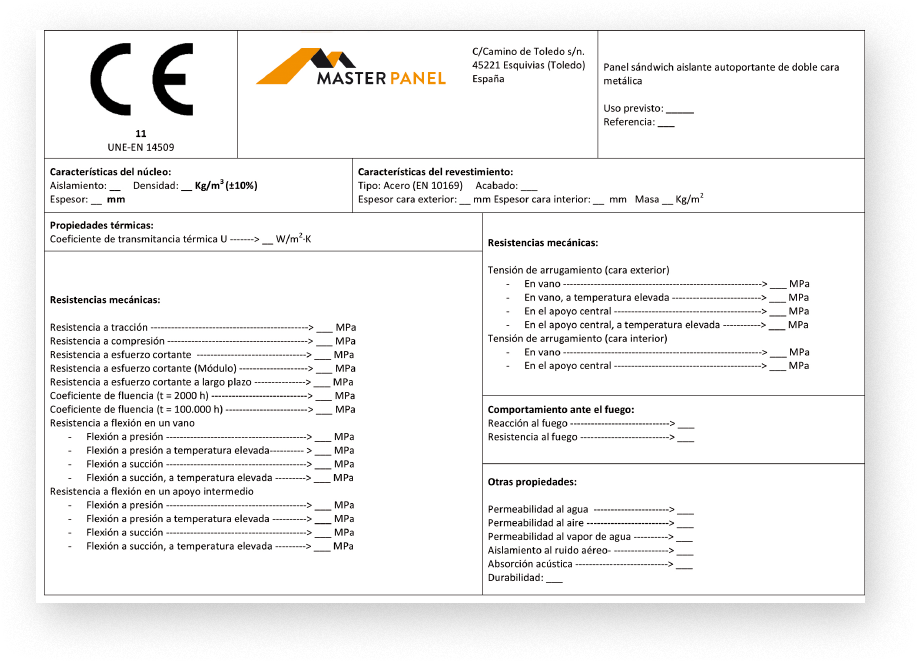

All of our products bear the CE mark, which lets our customers know that our profiles and panels comply with current legislation.

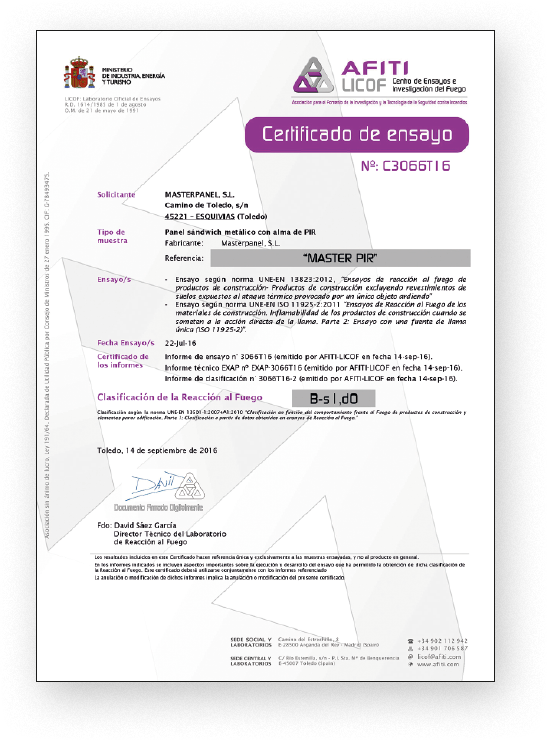

REACTION TO FIRE

Certification is obtained in The Spanish Association for the Promotion of Research and Fire Safety Technology (AFITI) laboratories, experts in the study of fire performance of multiple products used in construction.

Certification obtained in The Spanish Association for the Promotion of Research and Fire Safety Technology (AFITI) laboratories, experts in the study of fire performance of multiple products used in construction.