We are Sandwich Panels Manufacturer

Since 2005, MASTER PANEL S.L. we are dedicated to the manufacture of polyurethane (PUR) and polyisocyanurate (PIR) sandwich panels for different sectors of the construction industry, combining the current architectural trends with the most demanding functional requirements.

As a sandwich panel distributor, we ensure that our deliveries are safe and efficient, nationally and internationally. We strive to offer a quality service, giving our customers the peace of mind of knowing that their materials will arrive at their destination in perfect condition and on time.

We have a team of professionals that will offer you a personalized service according to your needs.

Products

Download the catalog with all the information about our sandwich panels.

What are the Master Sandwich Panels?

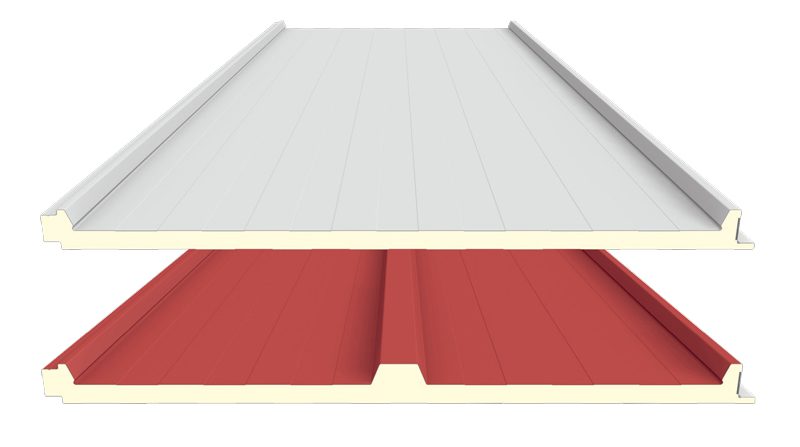

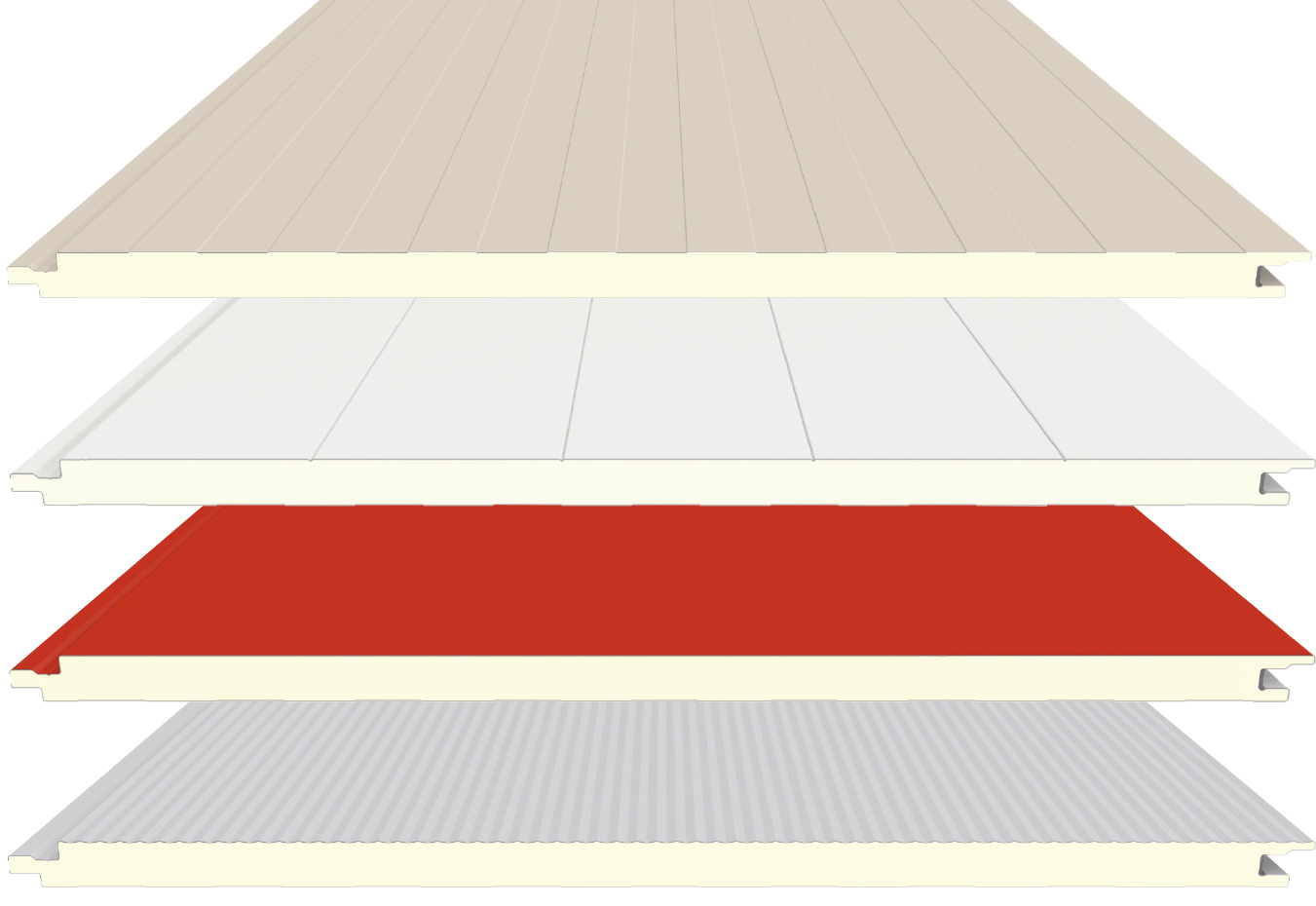

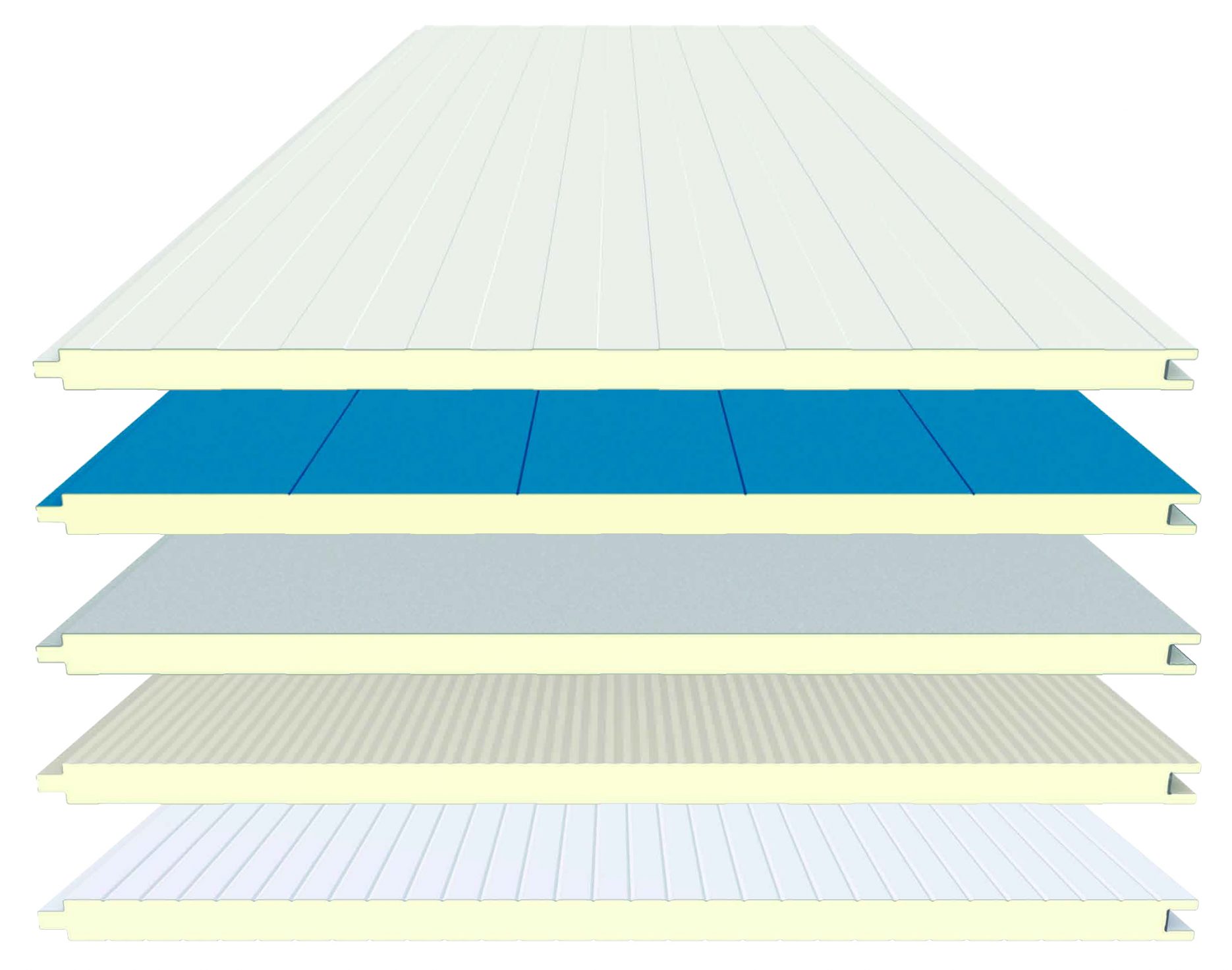

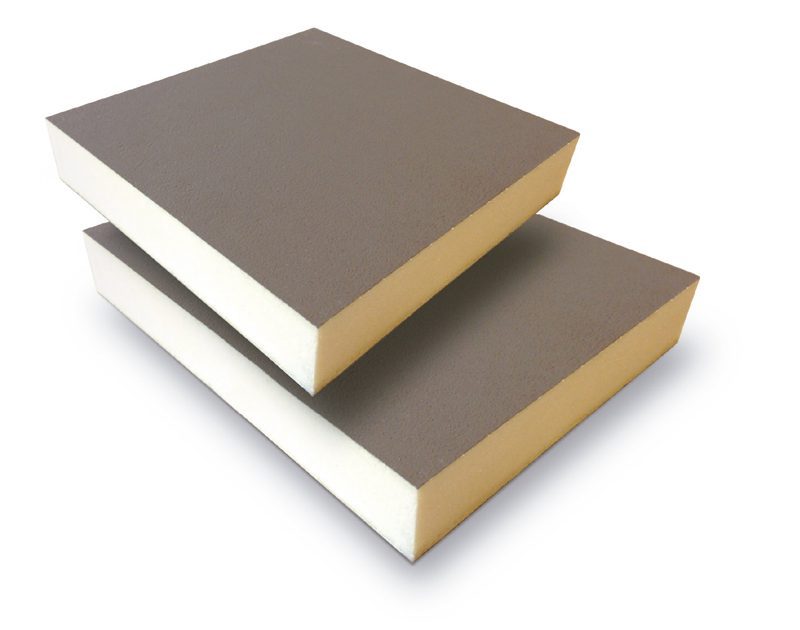

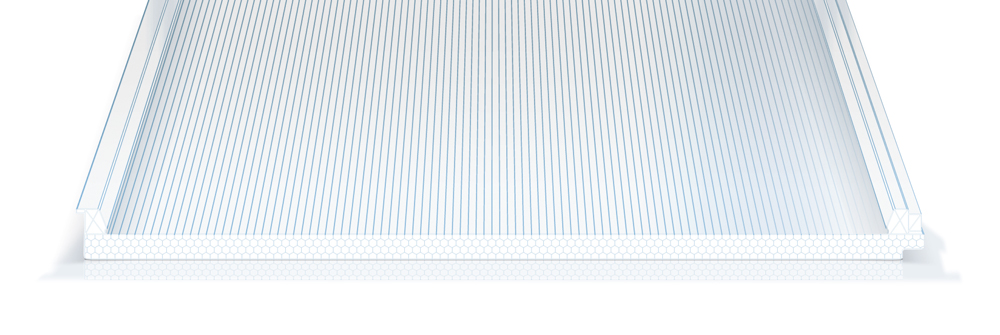

The sandwich panel can be defined as a “sandwich” type structure, the result of the combination of an insulating core filled with rigid polyurethane foam and two metallic outer sheets, generally made of hot-dipped galvanized steel and subsequently pre-painted in different qualities and finishes.

During the manufacturing process, the core expands, adhering completely to the covering sheets without the use of any type of adhesive.

This structure gives it high mechanical strength, excellent thermal and acoustic insulation, and greater flexibility compared to traditional building materials. In addition, its installation is quick and easy, which reduces costs and construction time. This makes it the best solution for the enclosure and cladding of all types of buildings.

In our sandwich panel factory, we ensure that the whole process is governed by the highest quality standards, ask for a free quotation.

Sandwich Panels Applications

The sandwich panels’ versatility allows them to be adaptable to a wide range of applications in the construction sector, including:

Their strength and easy assembly make them ideal for industrial buildings, warehouses, workshops and shopping centers.

Sandwich panels are essential in the design of modular buildings, including pre-fabricated offices, portable or permanent housing modules, and school classrooms.

Thanks to their thermal insulation capacity, refrigeration panels are ideal for use in the agro-food sector in the construction of warehouses, farms and mainly in cold rooms that help in the freezing and deep-freezing of foodstuffs.

Its insulating capacity and aesthetic variety facilitates its use on roofs and building walls, improving energy performance and offering a modern and attractive image.

They are an effective solution for the rehabilitation and improvement of energy efficiency in existing buildings, thanks to their easy installation on pre-existing structures.

Sandwich Panels Advantages

Sandwich panels have multiple advantages in their use in the construction area:

Thermal & acoustic insulation

Sandwich panels provide excellent thermal insulation, which helps to maintain required indoor temperatures, whether in an industrial warehouse, office or residential building, or in more demanding facilities such as cold storage rooms, resulting in significant savings in long-term heating and cooling costs.

In addition, sandwich panels are ideal for reducing noise, making them especially useful in the construction of engine halls and recording studios.

Easy to install

The sandwich panels installation is simple and easy to do, which reduces construction times and, consequently, costs, as they are ready to be put in place, which means that no additional labor is required for their fabrication. In addition, their reduced size and weight make them safer and easier to handle.

Durability

Because of the materials used in its manufacture, the insulating sandwich panel is able to withstand adverse climatic conditions. The excellent chemical and biological resistance of polyurethane, its high stability even under special conditions (extreme temperatures, very humid environments) and the wide range of steel coatings that adapt to any environmental condition, polyurethane panels can offer the best guarantee of durability.

Watertightness

The characteristics of sandwich panels are useful to prevent water seepage, due to their structure that prevents water and humidity from seeping into the insulating foam core.

Cost reduction

Sandwich sheets require minimal maintenance over time, reducing maintenance costs and the need for repairs, whether in industrial or residential buildings, as well as reducing energy costs and construction time.

Customized design

Sandwich panels are very versatile, they can be customized in accordance with the type of panel, type of core, finish, colors and sizes.

Do not hesitate to contact us to help you with whatever you need.

Frequently Asked Questions about Sandwich Panels

How long does a sandwich panel last?

Masterpanel sandwich panels can have a useful life of more than 30 years due to their material properties and if properly maintained.. Read more

How many degrees does a sandwich panel insulate?

To relate how many degrees a sandwich panel can insulate, several factors must be taken into account, including the type of core material and its thickness, as well as environmental conditions. Here is a simplified guide to understanding the temperature insulation capacity of a sandwich panel. Read more

How much weight does a sandwich panel bear?

There is no specific weight, each case is unique and has its own characteristics, depending on the thickness of the panel, thickness of the steel, and their lengths, may vary, although in the following guide we calculate depending on the thickness which can be the weight that can support the panel. Read more. Read more

How to install a sandwich panel?

The assembly and installation of sandwich panels is a process that must be done with care in the handling of the panels, so it is important to follow a series of good practices that help to install them in the safest and most efficient way possible.. Read more